As vaccine production increases, how should environmental monitoring respond?

- 2021-06-22

- 1423

- Esky Purify

In order to meet the current demand for vaccines, sterile production capacity must be rapidly increased. This means that environmental monitoring programs must also be quickly adapted.

Regulatory considerations:

Regulatory requirements do not change regardless of the scale of production. If production scales up to other geographic regions, you may need to meet other requirements in your region. For example, in the U.S. market, you must comply with Food and Drug Administration (FDA) guidelines for sterile processing. Most other markets require compliance with the European Union's (EU) harmonized Program for International Cooperation in the Inspection of Medicinal Products (PIC/S) and the World Health Organization's (WHO) Good Manufacturing Practices (GMPs).

Production is expanding rapidly:

In order to meet the current demand for vaccines, sterile production capacity must be rapidly scaled up. This means that environmental monitoring programs must also be quickly matched. Thoughtful planning will help.

Integrating the software and hardware of a monitoring system to work simultaneously, such as the TSI FMS online particle monitoring system, can save months of engineering time. Integrated systems reduce the number of suppliers and simplify validation. Standardized connectivity, such as OPC UA, can simplify the integration of environmental monitoring with other critical systems such as laboratory information management systems (LIMS) and enable 4.0 for your pharmaceutical equipment facility.

Partnering with a manufacturer of environmental monitoring equipment with extensive experience, such as TSI Instruments for the pharmaceutical/life sciences industry sector, is key. These suppliers must understand their markets and the regulatory requirements for their products (e.g. ISO 21501-4; ISO 14698-1; 21 CFR Part 11). Local system integrators can help with system design and installation, and provide service and calibration to simplify maintenance.

Productivity gains:

The global demand for sterile processing capacity is not going to subside anytime soon, so expanding EMR planning is in line with future expectations. While we hope that the global pandemic situation can end soon, for the current situation, the need for new crown vaccines is inevitable - and the industry-wide trend toward biologics and advanced therapeutic medicines (ATMPs) has increased the need for aseptic processing. To meet this demand, your environmental monitoring facility shouldn't slow down your manufacturing process now or in the future. Implementing an automated system can help you streamline your environmental monitoring program.

Expanding your production will not result in an increase in the proportion of production personnel, nor will it result in an increase in the size of your quality control (QC) staff. Therefore, just like your production process, your testing needs to become more automated to keep up and keep your systems compatible.

Eliminate manual processing steps and upgrade to an automated system for more environmental monitoring procedures. Automation brings the benefits of improved data integrity and reduced process risk. Improved data integrity comes from eliminating the opportunity for human error, as well as automatically storing data in a secure database where it is always easily accessible. Risk is reduced because more data is available to better understand the process and data can be constantly evaluated in real time so personnel can react immediately to poor results. This achieves improved quality and reduced downtime - both of which are critical to meeting the volume of market demand for life-saving vaccines.

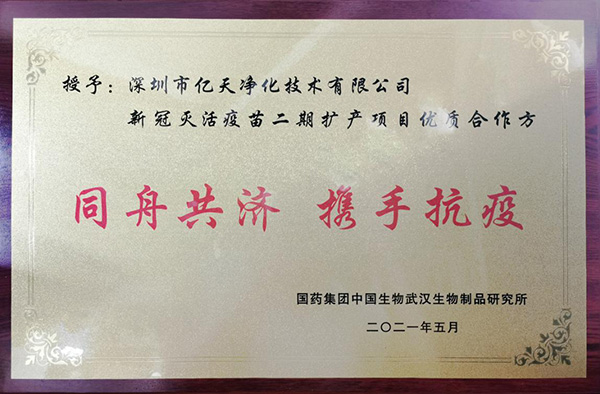

As a gold medal agent of TSI in South China, Esky Purify has been awarded the title of TSI's best agent for many times, and is a member of the Directors' Club. After 16 years of accumulation in the industry, we have not only become an excellent agent of scientific instruments and an authorized technical maintenance center, but also an excellent system integrator of controlled environment. In this year, we participated in the vaccine production project of Wusheng Institute, providing particle and bacterioplankton on-line monitoring equipment and systems to protect the vaccine production workshop and filling, and won the title of "in the same boat, hand in hand to fight against the epidemic" quality partner issued by the owner.

Home

Home Product

Product News

News phone

phone