Standards for the ABCD classification of clean areas in pharmaceutical factories

- 2023-03-02

- 1170

- Esky Purify

Criteria for classifying the clean area of a pharmaceutical factory into ABCD levels

Pharmaceutical clean area can be divided into four levels of ABCD area, pharmaceutical industry clean area is to particles and microorganisms as the main object of control, but also its environmental temperature and humidity, differential pressure, illuminance, noise and other provisions. Pharmaceutical industry clean plant air cleanliness level see GMP (2010), the provisions of the ABCD four levels. So, what is the standard of ABCD level for the division of clean area of pharmaceutical factory?

Class A: High-risk operation area

For example: filling areas, areas where stoppered drums, open top ampoules, open top vials, and areas where aseptic assembly or connection operations are performed. Laminar flow benches (hoods) are often used to maintain the environmental conditions in this area. The laminar flow system must have a uniform air supply in its working area with an air velocity of 0.36-0.54 m/s (guideline value). Data shall be available to demonstrate the status of the laminar flow and shall be verified. Unidirectional flow or lower air velocities may be used in confined isolation operators or glove boxes.

Class B: The background area in which Class A zones for high-risk operations such as aseptic preparation and filling are located.

Levels C and D: refer to clean operation areas of lower importance in the production of aseptic drugs.

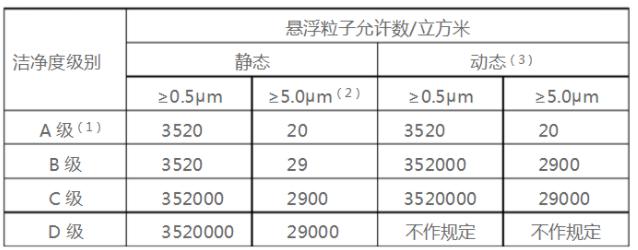

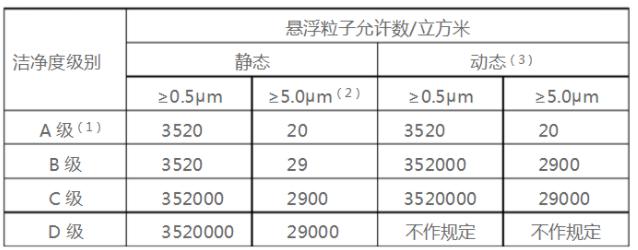

The standards for airborne particles according to the ABCD level are specified in the table below:

Summarize: A, B is equivalent to a hundred clean area, A background environment to be higher, more stringent requirements. level C is equivalent to 10,000 clean area, level D is equivalent to 100,000 clean area.

In order to confirm the level of class A clean area, the sampling volume of each sampling point shall not be less than 1 cubic meter, the level of airborne suspended particles in class A clean area is ISO4.8, with ≥5.0um suspended particles as the limit standard. the level of airborne suspended particles in class B clean area (static) is ISO5, which includes two kinds of suspended particles of the table size at the same time. For Class C clean areas (static and dynamic) the airborne particles are classified as ISO 7 and ISO 8. For Class D clean areas (static) the airborne particles are classified as ISO 8. The test methods can be found in ISO 14644-1.

Home

Home Product

Product News

News phone

phone