High-efficiency filter guide | Introduction to HEPA and ULPA filters

- 2023-02-13

- 1036

- Esky Purify

High-efficiency filters are an essential part of the controlled environment ventilation system. HEPA and ULPA filters are devices used to filter particles in the controlled environment air, and they are usually used to remove particles of dust and all kinds of suspended matter above 0.1um in the controlled environment air in order to provide cleaner indoor air. Therefore, they are commonly used at the end of the filtration system and are an important part of air purification equipment such as cleanroom FFUs, clean benches, and laminar flow transfer windows. Covering electronic panel semiconductor industry, data room, medical disease control, biological laboratory, animal laboratory, environmental protection and other fields.

PART 01

Main differences between HEPA and ULPA filters

HEPA and ULPA filters function in the same way and both can effectively purify indoor air, but there is a big difference in performance. Here are the main differences between the two types of air filters:

ULPA filters have higher filtration efficiency.

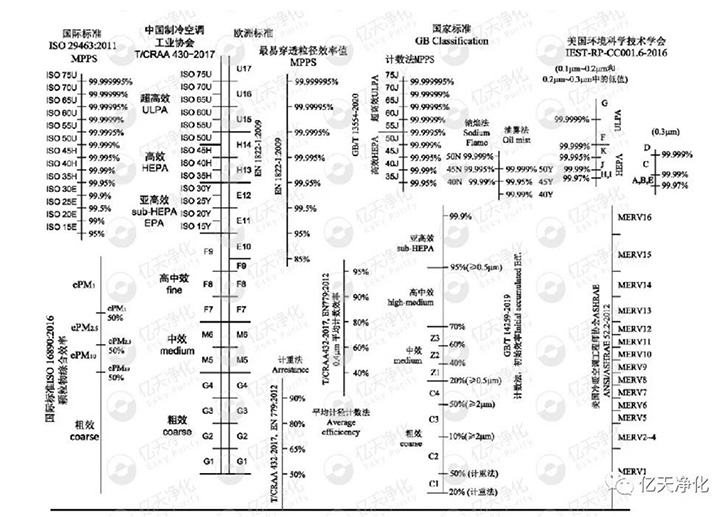

Air Filter Standards (Filtration Efficiency Comparison)

The efficiency of HEPA filter is ≥99.95% according to mpps counting method, HEPA filter can filter ≥0.3 micron particles, including pollen, dust, oil mist, etc.. And ULPA filter has higher filtration efficiency, ULPA filter efficiency ≥99.9995%, filtering ≥0.1 micron particles.

ULPA filter has better ISO rating

ULPA filters can provide ISO Class 3 cleanliness to the work area, while HEPA filters can provide ISO Class 5 cleanliness to the work area. As a result, the use of ULPA filters provides better product protection in production environments with higher cleanliness requirements.

HEPA filters have lower resistance

HEPA air filters have less resistance than ULPA air filters, allowing for greater operational savings and lower costs.

PART 02

Product Selection of HEPA and ULPA Filters for Yiten Purification

V type high efficiency filter (HEPA)

V-type high-efficiency filter (HEPA), divided into flangeless and single-flange, adopts ultra-fine glass fiber filter paper, made by combining multiple pieces of non-spacer filter elements and strictly sealing, featuring large filtration area, low resistance, long service life (up to 2-3 times that of the traditional spacer filters), and a wide range of applications, and it is usually suitable for air-conditioning and ventilation systems.

Filter testing standards according to: EN1822-1:2009

Filtration efficiency: H13 H14

Main features: long life, large rated air volume, high dust capacity; large filtering area, low resistance, compact structure; applicable to fixed air volume and variable air volume systems.

Main applications: central air conditioning end filtration, ventilation system end filtration, subway, nuclear industry, defense industry, etc.

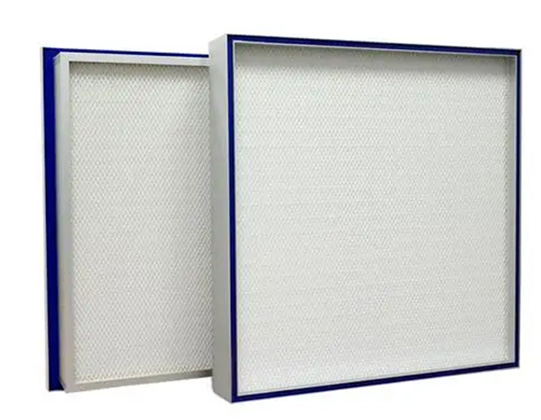

High efficiency filter without partition (ULPA&HEPA)

ULPA & HEPA (high efficiency filter without partition) is a high-efficiency filtration device made of dense pleated filter element, metal mesh cover and aluminum frame, which is suitable for fine filtration at the end of unidirectional flow and non-unidirectional flow cleanroom purification projects with strict requirements and can filter fine particles of dust above ≥0.1μm.

Filter testing standards based on: EN1822-1:2009

Filtration efficiency: H13 H14 U15

Product features: large filtration area, simple structure, high efficiency of intercepting dust, long service life, high humidity environment with special water-resistant glass fiber filter paper.

Main applications: clean engineering end filtration system, local purification equipment end filtration, clean operating room end filtration

PTFE plate high efficiency filter (ULPA&HEPA)

PTFE high-efficiency filter (ULPA&HEPA) is a new type of filter made of excellent performance PTFE filter paper as raw material and hot melt adhesive as the separator of the filter material, with a wide range of filtration efficiency that can meet the requirements of H13--U16@ISO16890, which can usually be used with FFUs and air supply devices such as air supply outlets and are widely used in microelectronics, semiconductors, bio-pharmaceuticals, It is widely used in microelectronics, semiconductors, biopharmaceuticals, data centers and other industries where cleanliness is required.

Product Features:

①Good energy-saving: compared with the traditional glass fiber filter, it has lower resistance characteristics and can save energy by more than 30%;

②Good reliability: PTFE filter has strong resistance to acid and alkali corrosion, good waterproofing, and can be applied to a variety of environmental requirements;

③ Good strength: the filter paper is not easy to be broken during production and transportation, which is convenient for testing and installation;

④High filtration efficiency: compact fiber structure, finer fiber diameter, higher capture efficiency for ultra-fine particles.

Filter testing standards based on: EN1822-1:2009

Filtration efficiency: H14, U15, U16

High-efficiency filter (HEPA) with liquid tank without partition

The high efficiency filter (HEPA) without partition liquid tank is the more ideal filtration equipment for clean room, clean operation room, biological clean room, aseptic room, and industrial clean room applications, and the liquid tank seal is more effective than the commonly used domestic mechanical extrusion seal.

Filter testing standards based on: EN1822-1:2009

Filtration efficiency: H13 H14

Product features: good sealing performance, easy installation, high efficiency, low resistance, low operating costs.

Main applications: clean engineering end filtration system, local purification equipment end filtration, clean operating room end filtration.

PART 03

Advantages of HEPA and ULPA Filters

● Cost savings

ESKY's HEPA and ULPA air filters have lower operating costs under the same operating conditions. For example: according to a filter in 3400m³/h air volume operation, fan efficiency to 50% calculation, if the average resistance of the filter operation increased by 100Pa, then the fan to overcome the filter resistance to run for 1 year (6000h) power consumption is 1133kWh, if the average resistance of the filter to reduce the value of 10Pa, then the annual power savings of 113kWh. Therefore, when choosing air filters, you should not be greedy for low prices, but also consider the expensive operating costs.

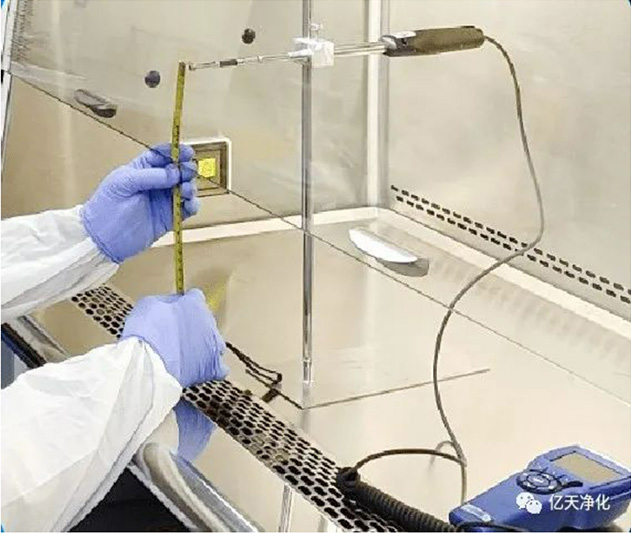

● Quality control

The production of high-efficiency filters is difficult, the sealing requirements are high, and the filter material is easy to break. Passing the high-efficiency filter is the basis of passing the project, so it is crucial to test the high-efficiency filter. Therefore, the inspection of HEPA filters is very important, and ESKY adopts a unit-by-unit inspection method for its HEPA filters.

? Quality department controls the quality according to the specifications and manufacturing process

? Multiple inspection equipment, from development to operation, from raw materials to finished products Multi-step control inspection

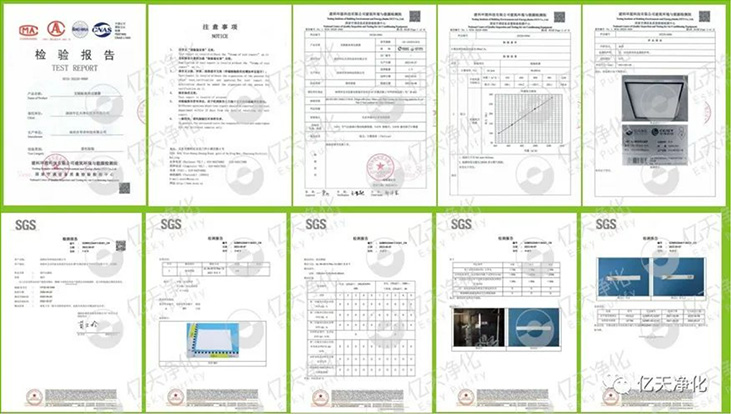

Full range of certifications

Each product has been certified by a variety of third-party professional testing organizations, safe, non-toxic, harmless and does not produce secondary pollution.

:: Fine-grained control

? Scientific matching of filter media based on sampling and analysis of air pollutants.

? Each formula is tested many times in the laboratory before being applied to industrial customers' clean engineering projects.

? Product wear rate, compressive strength and density are controlled to be optimal.

Home

Home Product

Product News

News phone

phone