Pollution control solutions for monitoring ultra-clean semiconductor environments (II)

- 2023-02-13

- 2170

- Esky Purify

semiconductor manufacturing

Semiconductor Manufacturing

Semiconductor shortages and competition for smaller process nodes in semiconductors. The shortage of integrated circuits (ICs) requires more output from the manufacturing process, so industry leaders are competing for smaller process nodes. These challenges require monitoring of airborne particle contamination to ensure risk-free products, increased yields (product yield), and successful cleanliness audits.TSI provides complete environmental monitoring solutions from nanoparticles to submicron particles with our highly sensitive particle counters to meet the semiconductor shortage and competition for smaller process nodes.

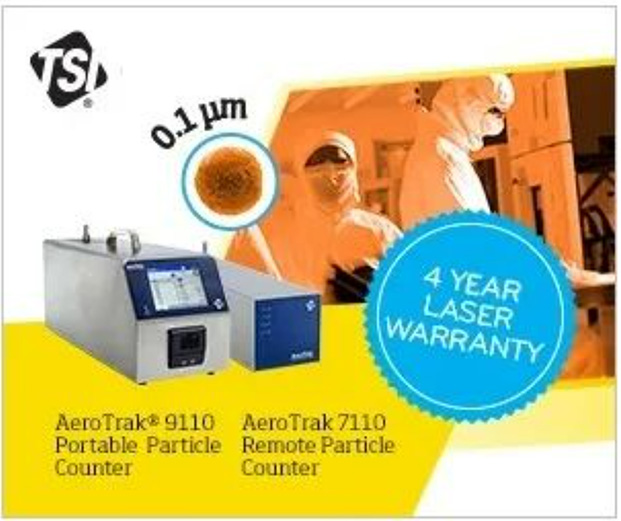

The TSI 10 nm Cleanroom Coalescing Particle Counter (CPC) and 0.1 μm Particle Counters (Remote Particle Counters and Portable Particle Counters) are the optimal combination to meet the critical needs of the semiconductor industry.

TSI has been providing high sensitivity particle counters for over 60 years, longer than any other particle counter company, and TSI instruments are used in national standards laboratories around the world that demand superior accuracy, repeatability and reliability. Never compromise on any manufacturing process - trust TSI to monitor everything.

0.1µm Measurement You Can Trust

The 1.0 CFM (28.3 L/min) AeroTrak® Remote Particle Counter Model 7110 and AeroTrak® Portable Particle Counter Model 9110 meet the demanding requirements of semiconductor cleanroom applications. Both instruments are backed by a 4-year laser warranty.

AeroTrak® Remote Particle Counter Model 7110

The Model 7110 Remote Particle Counter is capable of detecting particles down to 0.1 μm! This is accomplished using patented HeNe laser technology with improved signal-to-noise ratio. The instrument is designed for clean room monitoring, process monitoring and filter testing applications. In addition, since the particle counter is used in conjunction with an external vacuum source, there is great flexibility in placing and configuring the system.

Particle counting data can be easily and continuously transferred to equipment monitoring systems such as the TSI FMS 5 for secure data collection and analysis. Specifically, when integrated with FMS 5, you have a powerful productivity tool with features such as statistical process control. These particle counters can also store up to 2000 sample records.

Model 7110 meets all the stringent requirements set forth in ISO 21501-4. It is calibrated with a NIST-traceable PSL sphere and uses recognized standards for particle detection, namely TSI's World Class Classifier and Condensation Particle Counter standards.

AeroTrak® Portable Particle Counter Model 9110

The Model 9110 Portable Particle Counter is capable of detecting particles down to 0.1 μm! Fully compliant with ISO-14644-1 standards, the Model 9110 is the best choice for Class 1 and Class 2 cleanroom classification. This instrument is ideal for cleanroom monitoring, process monitoring and filter testing applications.

The Model 9110 generates ISO 14644-1 compliant pass or non-compliant reports via a printer and the accompanying TrakProTM Lite Secure download software. It can be used as a stand-alone particle counter or integrated into online particle monitoring systems such as the FMS 5. Data storage capacity is up to 250 zones, 999 locations and 10,000 samples.

Home

Home Product

Product News

News phone

phone