[Dry Goods] Unit Conversion of Dust Particle Counters

- 2023-04-11

- 1366

- Esky Purify

Dust particle counter in the measurement environment after the normal start, running after the sampling time, the instrument screen can display the accurate measurement value, but generally through the unit display, because different models of counters display different units, so before using the instrument, we first classify the instrument by flow rate.

Currently on the market there are mainly the following four flow rate of particle counters, respectively, 2.83L / Min, 28.3L / Min, 50L / Min, 100L / Min. instrument data units are counting unit Σ #, concentration unit Σ # / L, Σ # / L, Σ # / FT ³, Σ # / M ³;.

The counting unit Σ# indicates the number of particles in the volume that has been sampled.

The concentration units Σ#/L, Σ#/FT³, Σ#/M³ are converted to the number of particles in 1L or 1FT³ or M³ regardless of the sampled volume.

The flow rate conversions are as follows

2.83 L/min = 0.00283 m³/min = 0.1 ft³/min

28.3 L/min = 0.0283 m³/min = 1 ft³/min

50L/min=0.050 m³/min ≈1.77ft³/min

100L/min=0.1 m³/min ≈3.53ft³/min

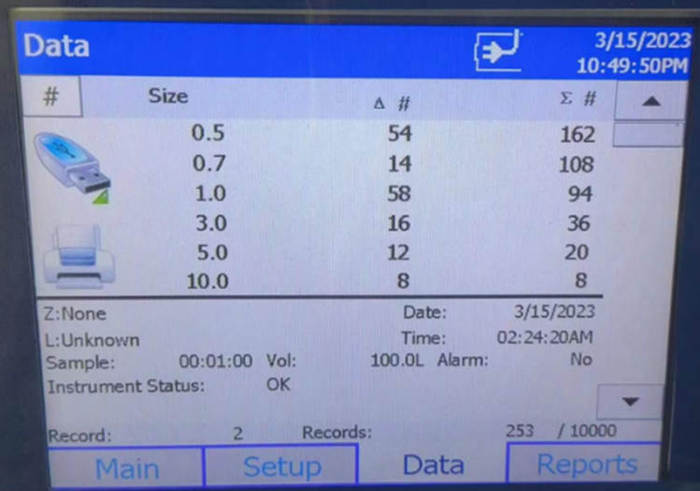

So what is the conversion rule for particle counts of different flow rates of dust particle counters? Here we will take 9500 as an example to introduce it to you. As shown in the figure:

The counting unit Σ# indicates the number of particles in the volume that has been sampled.

The concentration units Σ#/L, Σ#/FT³, Σ#/M³ are converted to the number of particles in 1L or 1FT³ or M³ regardless of the sampled volume.

The flow rate conversions are as follows

2.83 L/min = 0.00283 m³/min = 0.1 ft³/min

28.3 L/min = 0.0283 m³/min = 1 ft³/min

50L/min=0.050 m³/min ≈1.77ft³/min

100L/min=0.1 m³/min ≈3.53ft³/min

So what is the conversion rule for particle counts of different flow rates of dust particle counters? Here we will take 9500 as an example to introduce it to you. As shown in the figure:

▲# : represents the differential value, which refers to the number of particles greater than or equal to the current channel less than the next channel.

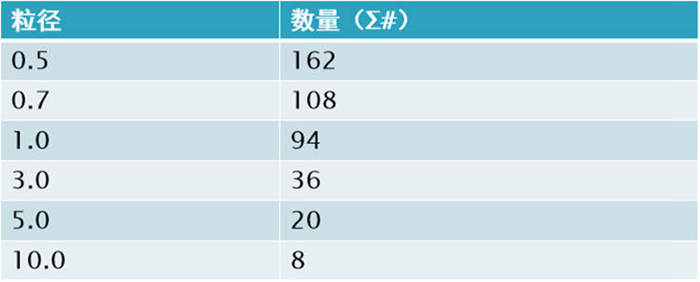

Σ#: represents the cumulative value, refers to the number of particles greater than or equal to the current channel less than the maximum detection limit of the instrument.

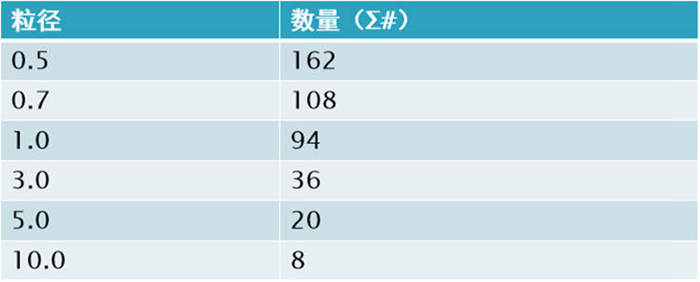

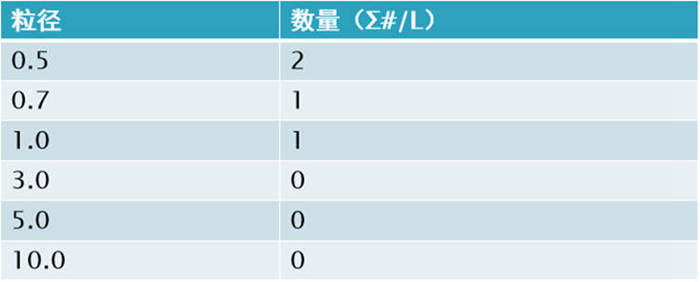

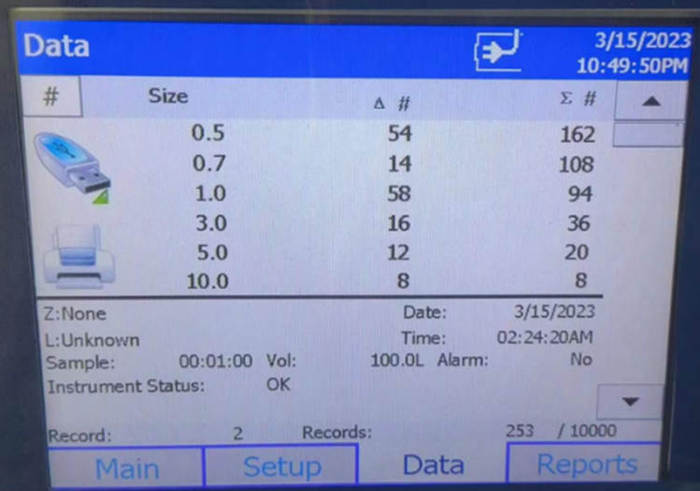

The 9500 runs for one minute, the sampling volume is 100L, the corresponding sampling data is shown in the figure below:

Σ#: represents the cumulative value, refers to the number of particles greater than or equal to the current channel less than the maximum detection limit of the instrument.

The 9500 runs for one minute, the sampling volume is 100L, the corresponding sampling data is shown in the figure below:

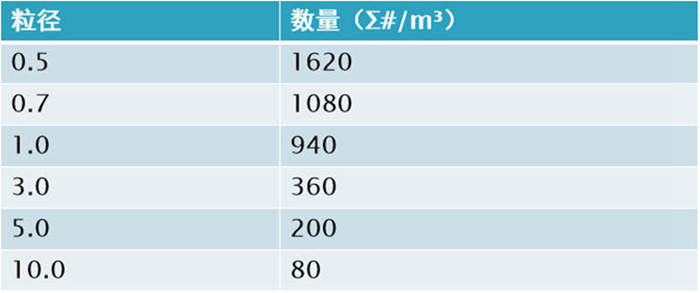

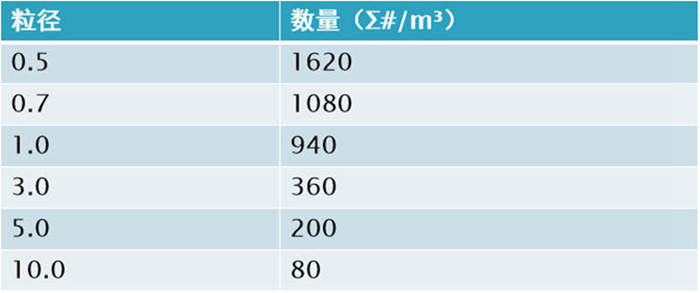

The above data corresponds to Σ# data, you can understand that Σ#/100L, then converted to Σ#/m³ is Σ#/1000L, the corresponding data is × (1000?100), the data are as follows:

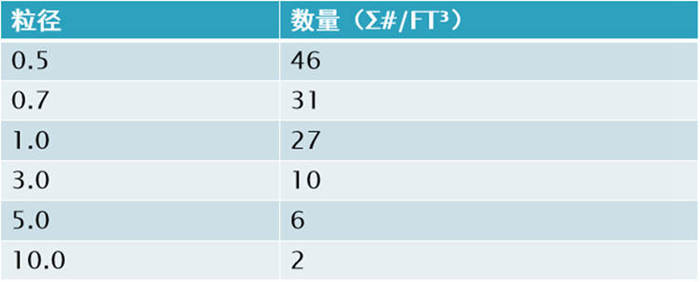

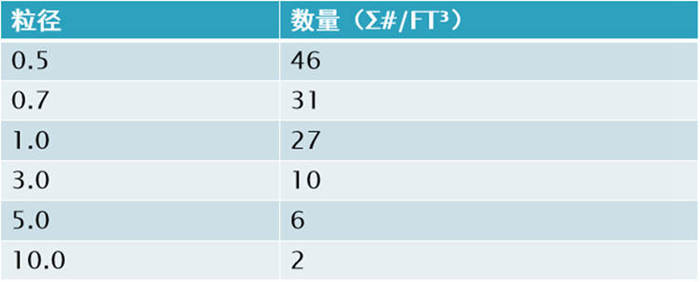

Then converted to Σ#/FT³ is Σ#/28.3L, the corresponding data is × (28.3?100), the data is converted as follows, TSI instrument decimal point rounding, Metone is one decimal point.

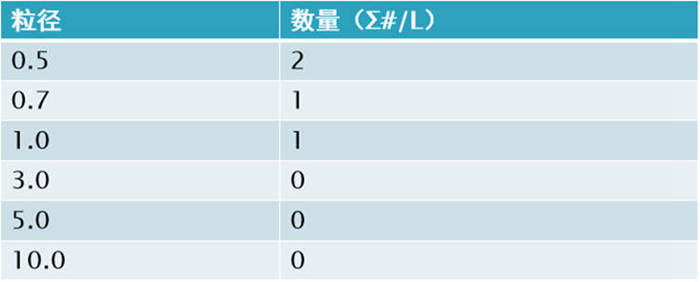

Then converted to Σ#/L, the corresponding data is × (1?100), the data converted as follows:

Metone is calculated by retaining one decimal place.

TSI is calculated by rounding to the nearest whole number.

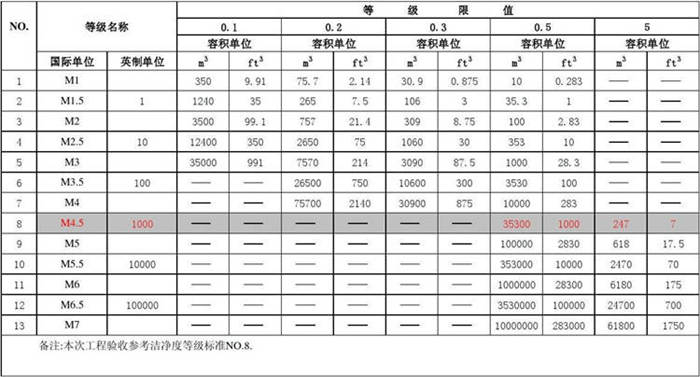

Cleanroom Classes

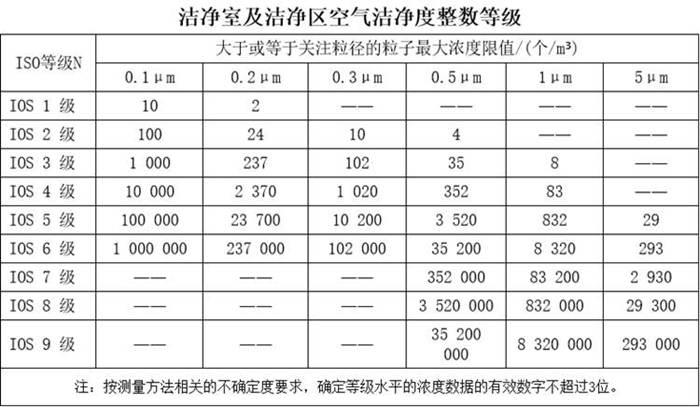

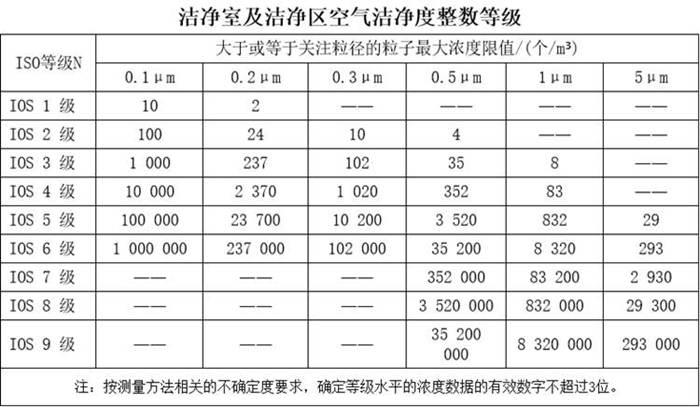

ISO14644 Cleanroom Class

ISO14644 Cleanroom Class

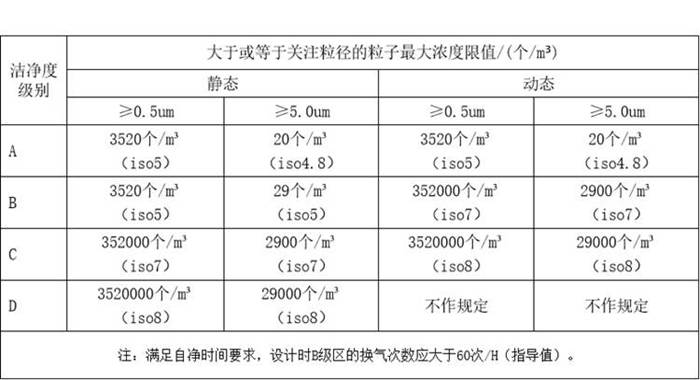

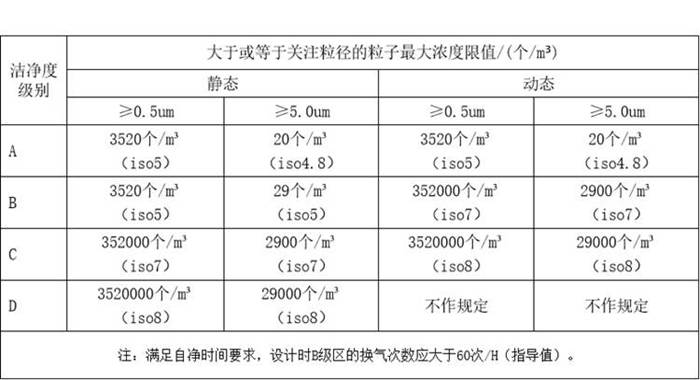

GMP Cleanroom Grade

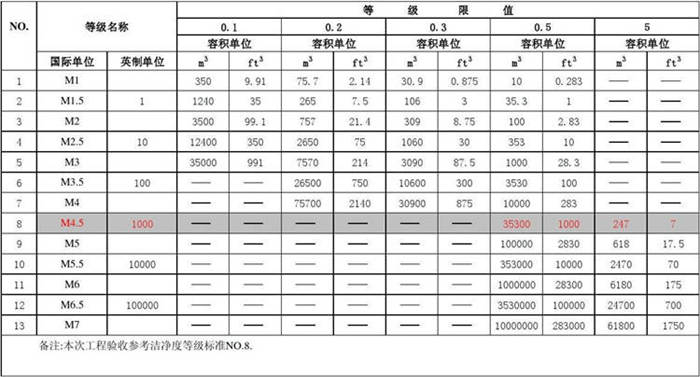

209E Cleanroom Class

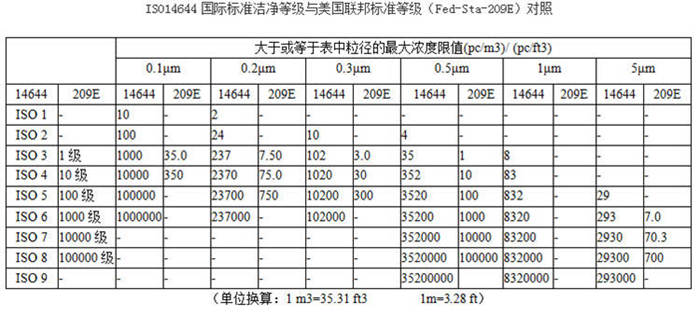

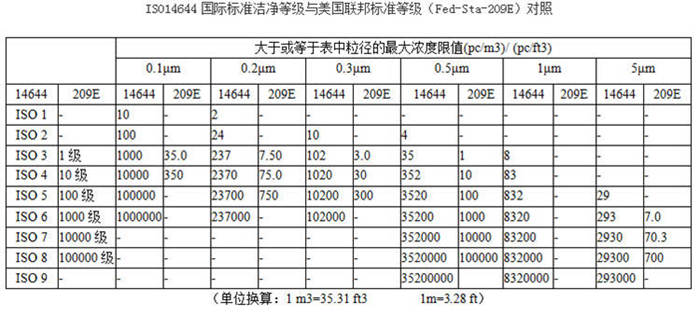

Comparison of ISO14644 International Standard Cleanroom Classes and U.S. Federal Standard Classes (Fed-STA-209E)

Home

Home Product

Product News

News phone

phone